- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

AM3V: The Next-Generation Flame Retardant Replacing ATO in PVC Compounds

Advanced Aluminum Magnesium Layered Double Hydroxide (LDH) Flame Retardant for Next-Generation PVC Compounds

Introduction

As industries worldwide accelerate their transition toward safer, cost-effective, and environmentally sustainable flame retardant solutions, the demand for high-performance alternatives to Antimony Trioxide (ATO) has reached unprecedented levels. AM3V represents a groundbreaking advancement in flame retardant technology—an innovative aluminum and magnesium co-precipitated layered double hydroxide (LDH) specifically engineered to revolutionize fire safety standards in PVC compounds.

Developed by KMT Industrial's world-class R&D team, AM3V delivers superior flame retardancy, dramatically reduced smoke density, and substantial cost savings, making it the ideal ATO replacement for demanding applications across cables, construction materials, automotive components, and industrial equipment. By replacing traditional ATO+ATH/MDH blends with AM3V, manufacturers can achieve equivalent or superior performance while significantly reducing environmental impact and production costs.

Why AM3V Stands Out

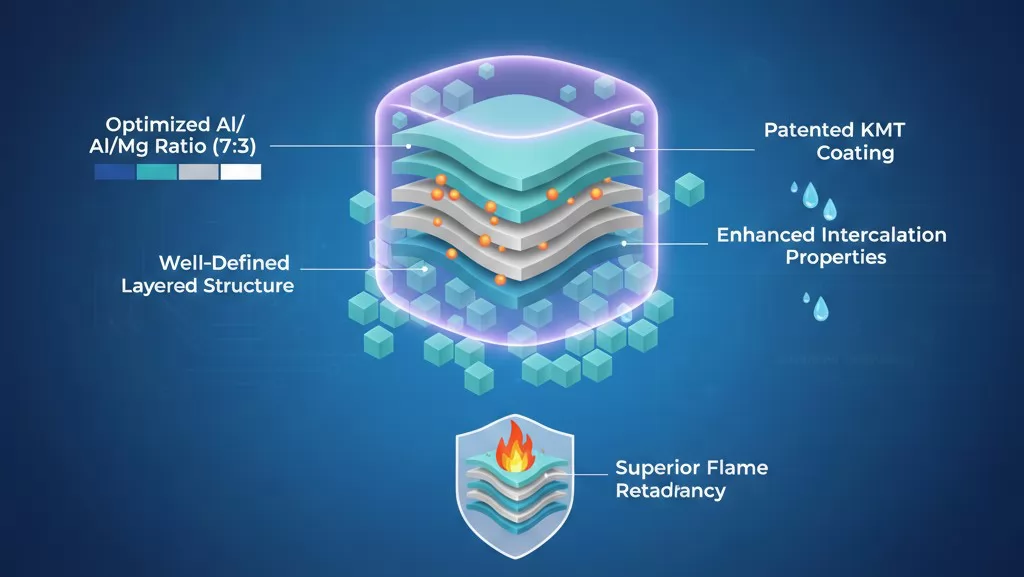

AM3V leverages KMT Industrial's proprietary co-precipitation technology, a sophisticated synthesis process that enables nanoscale synergy between magnesium and aluminum hydroxide layers. This innovative approach creates a uniquely structured layered double hydroxide with exceptional flame retardant properties that far exceed traditional micron-level physical blends.

Advanced Co-Precipitation Technology

Unlike conventional flame retardant formulations that simply mix aluminum trihydrate (ATH) or magnesium dihydroxide (MDH) with ATO, AM3V's co-precipitation process creates a homogeneous molecular structure at the nanoscale. This results in:

- Optimized Al/Mg Ratio (7:3): Precisely engineered stoichiometry for maximum flame suppression efficiency

- Well-Defined Layered Structure: Uniform crystal morphology ensuring consistent performance

- Enhanced Intercalation Properties: Superior ability to trap and release water molecules during thermal decomposition

- Patented KMT Coating: Surface modification technology that improves dispersion and compatibility with PVC matrices

Superior Flame Retardancy

Achieves a Limited Oxygen Index (LOI) of ≥30%, matching or exceeding traditional ATO-based formulations while delivering enhanced char formation and drip prevention.

Dramatic Smoke Reduction

Up to 56% lower smoke density compared to ATO (28.34 vs. 64.51 in testing), critical for maintaining visibility and safety during fire emergencies in confined spaces.

Exceptional Cost Efficiency

Using 40 phr of AM3V delivers equivalent performance to 5 phr of ATO at approximately 1/15th the material cost, transforming the economics of flame retardant formulations.

Environmental Sustainability

Replaces traditional ATO+ATH/MDH blends with a non-toxic, heavy-metal-free alternative, aligning with global sustainability goals and evolving regulatory requirements.

Versatile Applications

Ideal for PVC compounds used in electrical cables, construction profiles, piping systems, automotive interiors, and industrial fire-sensitive environments.

Easy Integration

Compatible with existing PVC processing equipment and formulations, minimizing transition costs and production downtime during material switching.

Performance Comparison

Comprehensive testing on standardized PVC formulations demonstrates AM3V's significant advantages over traditional ATO and ATH (40CD) blends. The following data represents results from controlled laboratory conditions using identical base formulations to ensure fair comparison.

Key Performance Insights

Equivalent Flame Retardancy

40 phr AM3V matches the LOI performance of 5 phr ATO (both achieving 30%), ensuring robust fire resistance that meets international safety standards including IEC 60332, UL 94, and BS 5852.

Superior Smoke Suppression

AM3V reduces maximum smoke density by 56% compared to ATO (28.34 vs. 64.51), a critical advantage for maintaining evacuation visibility and reducing toxic exposure in fire scenarios.

Outstanding Cost Efficiency

AM3V's significantly lower material cost (approximately 1/15th of ATO) makes it a transformative solution for manufacturers seeking to reduce production costs without compromising safety standards.

| Property | AM3V (40 phr) | ATH (40 phr) | ATO (5 phr) |

|---|---|---|---|

| Density (g/cm³) | 1.46 | 1.526 | 1.494 |

| Limited Oxygen Index (%) | 30 | 27 | 30 |

| Tensile Strength (MPa) | 13.216 | 15.694 | 16.162 |

| Elongation at Break (%) | 273.906 | 313.271 | 312.772 |

| Maximum Smoke Density | 28.34 | 50.56 | 64.51 |

| Smoke Density Rate | 18.95 | 33.25 | 43.74 |

Technical Specifications

AM3V is manufactured to rigorous quality standards with precise control over chemical composition and physical properties. The following specifications ensure consistent performance across all batches.

| Property | Specification | Test Method |

|---|---|---|

| Grade | AM3V | - |

| Al³⁺/Mg²⁺ Mol Ratio | 7:3 ± 0.2 | ICP-AES |

| CaO (%) | ≤ 0.10 | EDXRF |

| Iron as Fe₂O₃ (%) | ≤ 0.15 | EDXRF |

| SiO₂ (%) | ≤ 0.15 | EDXRF |

| Al₂O₃ (%) | ≤ 0.15 | EDXRF |

| Insoluble Matter (%) | ≤ 0.10 | Gravimetric |

| Loss on Ignition (%) | ≥ 30 | Thermogravimetric |

| Whiteness (R457) (%) | ≥ 95 | Colorimeter |

| Moisture (%) | ≤ 0.5 | KF Titration |

| BET Surface Area (m²/g) | 5–7 | Gas Adsorption |

| Density (g/cm³) | 2.3 | Pycnometer |

| Particle Size D50 (μm) | 3.0–4.0 | Laser Diffraction |

| Coating | Proprietary KMT Coating | - |

Chemical Composition

AM3V is composed of carefully balanced magnesium and aluminum hydroxides:

Magnesium Hydroxide

Formula: Mg(OH)₂

CAS No.: 1309-42-8

EC No.: 215-170-3

Aluminum Hydroxide

Formula: Al(OH)₃

CAS No.: 21645-51-2

EC No.: 244-492-7

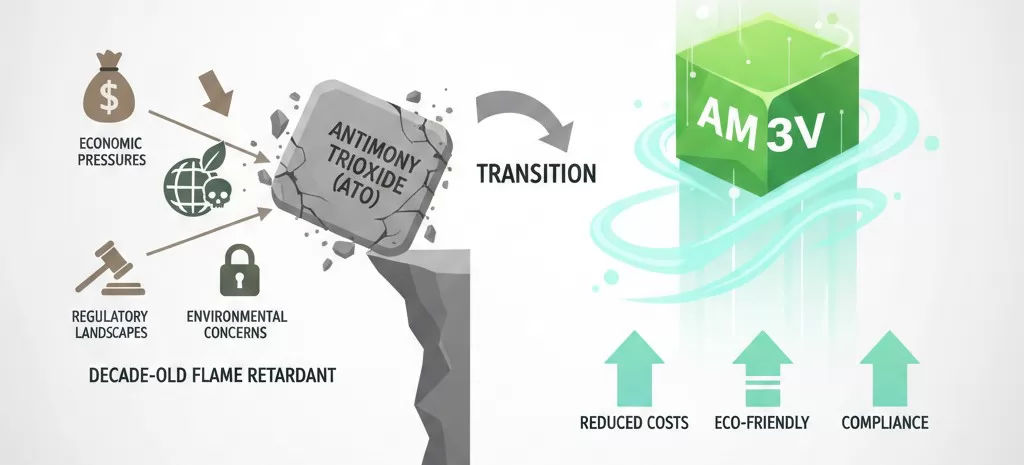

Why Replace ATO?

Antimony Trioxide (ATO) has served as a cornerstone flame retardant synergist for decades, but mounting economic pressures, environmental concerns, and evolving regulatory landscapes are accelerating the industry's transition toward sustainable alternatives. AM3V addresses these challenges head-on.

Economic Pressure

ATO prices have experienced significant volatility, with costs often exceeding $8,000-12,000 per metric ton. AM3V offers dramatically lower material costs (approximately 1/15th of ATO) while delivering equivalent flame retardant performance, directly improving profit margins.

Environmental & Regulatory Concerns

ATO is classified as a Substance of Very High Concern (SVHC) under REACH regulations due to its classification as a suspected carcinogen. The EU's evolving regulations and global push toward safer alternatives make ATO replacement increasingly critical for market access.

Enhanced Safety Performance

With smoke being the primary cause of fatalities in fire incidents, AM3V's 56% smoke reduction compared to ATO provides superior protection for building occupants, emergency responders, and equipment in critical infrastructure applications.

Sustainability Leadership

Replacing ATO with AM3V supports corporate ESG (Environmental, Social, and Governance) goals and demonstrates commitment to sustainable manufacturing practices, increasingly important for B2B relationships and end-consumer preferences.

Supply Chain Security

ATO production is concentrated in a limited number of countries, creating supply chain vulnerabilities. AM3V's raw materials are more widely available, reducing geopolitical risks and ensuring more stable procurement.

Future-Proof Compliance

Proactively switching to AM3V positions manufacturers ahead of regulatory changes, avoiding costly reformulation deadlines and potential market exclusion as restrictions on ATO continue to expand globally.

Applications

AM3V is specifically engineered and optimized for Fire-Retardant Low-Smoke (FRLS) PVC compounds, meeting the stringent requirements of various industrial and commercial applications where fire safety is paramount.

Electrical & Data Cables

Power cables, control cables, telecommunication cables, and data center cabling systems requiring FRLS compliance and enhanced fire safety for enclosed spaces.

Construction Materials

Window profiles, door frames, wall panels, flooring, roofing membranes, and other building materials demanding fire resistance and low smoke emission.

Automotive Components

Interior trim panels, wiring harnesses, under-hood components, and other automotive parts requiring compliance with FMVSS 302 and similar fire safety standards.

Industrial Equipment

Conveyor belts, protective coverings, machinery enclosures, and processing equipment in chemical, pharmaceutical, and manufacturing facilities.

Industry Standards Compliance

AM3V formulations can be engineered to meet major international fire safety standards:

Construction & Building

EN 13501-1 (Euroclasses), BS 476, DIN 4102 (B1/B2), GB 8624, ASTM E84

Cables & Electrical

IEC 60332, IEC 60502, UL 1581, CSA C22.2, RoHS Compliant

Transportation

FMVSS 302, ASTM D5132, EN 45545 (Rail), FAR 25.853 (Aviation)

Industry Success Stories

Leading manufacturers across multiple industries have successfully transitioned to AM3V, achieving significant improvements in safety performance and cost efficiency.

European Cable Manufacturer

Challenge: Rising ATO costs and REACH compliance concerns

Solution: Full conversion to AM3V-based FRLS PVC

Result: 87% material cost reduction, eliminated SVHC compliance risk, maintained all certifications

Asian Construction Profile Producer

Challenge: Meeting new low-smoke building codes

Solution: Reformulated profiles with AM3V + ATH blend

Result: 45% smoke density reduction, passed stricter B1 fire rating, won major infrastructure project

North American Automotive Supplier

Challenge: OEM sustainability requirements

Solution: Replaced ATO with AM3V in interior components

Result: Achieved supplier sustainability certification, improved VOC emissions profile

Frequently Asked Questions

Based on testing and customer applications, AM3V is typically used at 35-45 parts per hundred resin (phr) to achieve equivalent flame retardancy to 5 phr ATO. The exact dosage depends on your specific formulation, target LOI requirements, and other performance parameters. Our technical team can provide formulation guidance tailored to your application.

AM3V is designed to balance flame retardancy with mechanical performance. While some adjustment to formulation may be needed compared to ATO systems, most customers find that standard PVC processing parameters and typical stabilizer packages work well with AM3V. The density advantage (1.46 vs 1.49 for ATO systems) can actually improve specific strength properties in some applications.

AM3V's optimized particle size (D50: 3.0-4.0 μm) and proprietary coating provide excellent dispersion and compatibility with PVC matrices. Processing temperatures and cycles are generally comparable to traditional ATH/MDH systems. The KMT coating technology minimizes moisture sensitivity and improves surface finish of finished products.

Yes, AM3V can be used in combination with other flame retardants including nano-clays, intumescent systems, and phosphorus-based additives. In fact, many customers achieve optimal results by combining AM3V with carefully selected complementary additives to fine-tune performance for specific requirements.

KMT Industrial provides comprehensive documentation including Technical Data Sheets (TDS), Material Safety Data Sheets (MSDS/SDS), REACH compliance statements, RoHS declarations, and technical support letters. Third-party certification and testing can be arranged upon request for specific market requirements.

Sample quantities (5-25 kg) are typically available within 1-2 weeks for evaluation. Bulk orders (metric tons) can be fulfilled within 4-6 weeks of confirmed order, with regular production schedules ensuring consistent supply. We maintain inventory at multiple regional distribution points to support just-in-time delivery requirements.

"Switching to AM3V transformed our cable manufacturing operation. We achieved 85% cost reduction on our flame retardant package, eliminated REACH compliance concerns, and actually improved our smoke ratings. KMT's technical support was exceptional throughout the transition."

Technical Director, European Cable Systems GmbH

Why Choose KMT Industrial?

KMT Industrial stands as a global leader in advanced flame retardant solutions, combining decades of materials science expertise with cutting-edge manufacturing capabilities to deliver products that exceed industry expectations.

Advanced R&D Capabilities

Our world-class research facility employs PhD-level chemists and materials scientists dedicated to continuous innovation in flame retardant technology, holding multiple patents in LDH synthesis and surface modification.

ISO Certifications

Full ISO 9001:2015 quality management certification, ISO 14001 environmental management, and ongoing implementation of ISO 45001 occupational health and safety standards across all manufacturing operations.

Global Supply Network

Manufacturing facilities and distribution centers across Asia, Europe, and the Americas ensure reliable supply and responsive service to customers worldwide, with regional technical support teams.

Dedicated Technical Support

Our application engineers work closely with customers to optimize formulations, troubleshoot processing issues, and develop customized solutions that meet specific performance requirements and regulatory standards.

Sustainability Commitment

KMT Industrial is committed to environmental stewardship, with continuous investment in green manufacturing processes, recyclable packaging, and development of products that support a more sustainable future.

Quality Consistency

Rigorous quality control testing at every production stage ensures batch-to-batch consistency, providing manufacturers with reliable material specifications and predictable processing characteristics.

Ready to Transform Your Flame Retardant Formulation?

Join the industry leaders who are switching to AM3V—the future of flame retardant technology. Request samples, technical data, or a consultation with our experts today.

Your Name*

Your Email*

-

2026-Jan-22AM3V: The Next-Generation Flame Retardant Replacing ATO in PVC CompoundsDiscover AM3V, KMT Industrial’s innovative flame retardant replacing ATO in PVC compounds. Achieve high LOI (≥30), low smoke density, and 1/15th the cost.

-

2026-Jan-19How Magnesium Hydroxide Affects Polymer Rheology and ProcessingDiscover how magnesium hydroxide (MDH) affects polymer rheology and processing. Learn expert solutions for optimizing extrusion, injection molding, and compounding of HFFR flame retardant compounds. Technical guide for polymer engineers and manufacturers.

-

2026-Jan-13How to Choose the Best Magnesium Hydroxide Flame Retardant SupplierSelecting the right MDH supplier is critical for HFFR performance. This guide covers technical grades, surface coatings, and global compliance. Learn more with KMT Industrial.

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products