English

- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

Hydromagnesite

Focuses on the research and development of Hydromagnesite. Annual production capacity exceeds 30,000 tons.

Products

Need More Help?

Give us a e-mail and chat with our team today!

Get Started

Hydromagnesite

Nature own fire retardant. Hydromagnesite Chemical formula: [3MgCO3 · Mg(OH)2 · 3H2O] This unique natural minerals is also known as HMH.

Discover the latest hydromagnesite price tailored to your specific needs!- KMT HM products comply with RoHs and REACH requirements.

- Processing temperature less than 200°C

- Packing: 25kg bag or big bag.

-

The price of hydromagnesite varies based on order volume and purity. Contact us for a competitive quote.

Contact Us Now

Description

Reviews

HM Series--- Flame retardant to replace Antimony Trioxide(ATO)

Introduction

Nature own fire retardant.

Hydromagnesite Chemical formula: [3MgCO3 · Mg(OH)2 · 3H2O]

This unique natural minerals is also known as HMH.

It is a proven fire retardant filler in a wide range of polymers and rubbers such as EVA, POE, polyethylene (PE), polyvinyl chloride (PVC), ethylene-propylene diene monomer (EPDM) and Nitrile Rubber (NBR).

Advantages

Low carbon green product from nature

Good replacement of ATO (15hpr HM2V=1phr ATO)

Reduce FR PVC smoke density

Good synergistic flame retardant of ATH, reduce compound cost.

Improve self-extinguish, easy pass UL test.

High whiteness, not cause compound color change because of it's high purity

Low density

Processing temperature less than 200°C

Packing: 25kg bag or big bag.

Unique fire retardant properties

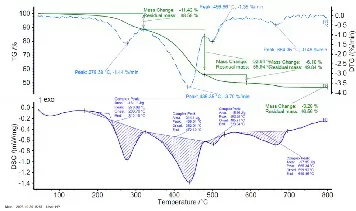

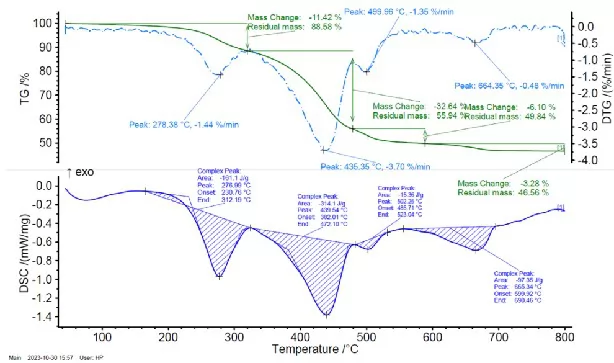

KMT HM has a unique 3-stage fire-retardant mechanism. Whereas the classical endothermic flame retardant fillers act by releasing water in a single action process, our premium HM product works as follows:

HM 3-stage fire retardant mechanism

Water is released at temperatures of ~220°C (thermal decomposition)

CO2 release at temperatures of ~330°C

At temperatures of ~560°C, particles accumulate at the surface of the burning polymer to form a stable cementitious char. This char inhibits the combustion process and thus the propagation of the fire through burning droplets.

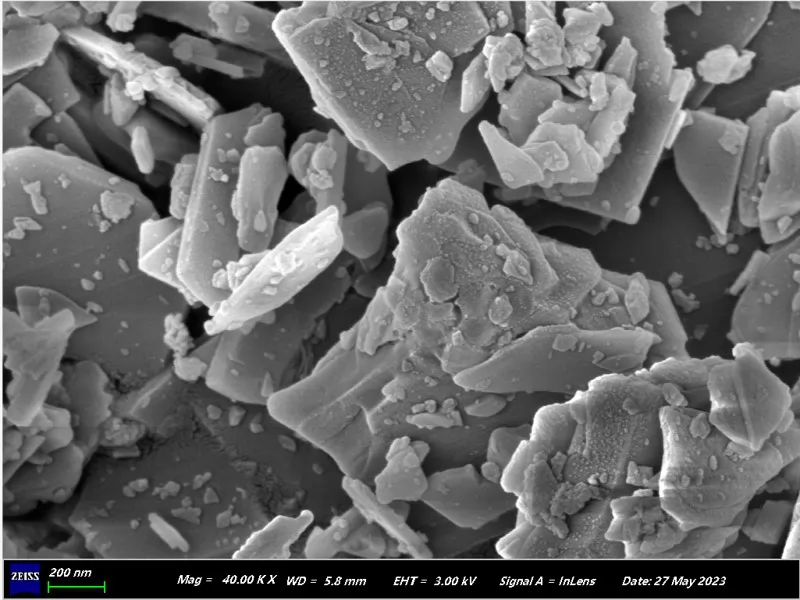

The platy, high surface area particles of our halogen-free mineral provide excellent properties when you use these as a functional filler in polymers.

The products’ high heat absorption protects polymers from rapid thermal degradation and the formation of combustible products.

KMT HM is halogen-free and eco-friendly with low smoke and toxicity.

HM has an excellent mechanical performance with a higher Oxygen index and low density. and the product with HM has stable color.

Package & Storage:

Jumbo bag package.

Transported as the common chemicals. Keep in dry, cool place and avoid direct sunlight.

Share your thoughts with us today!

Showing

Lina Chen - CN

5/5 stars

Apr 09.2025

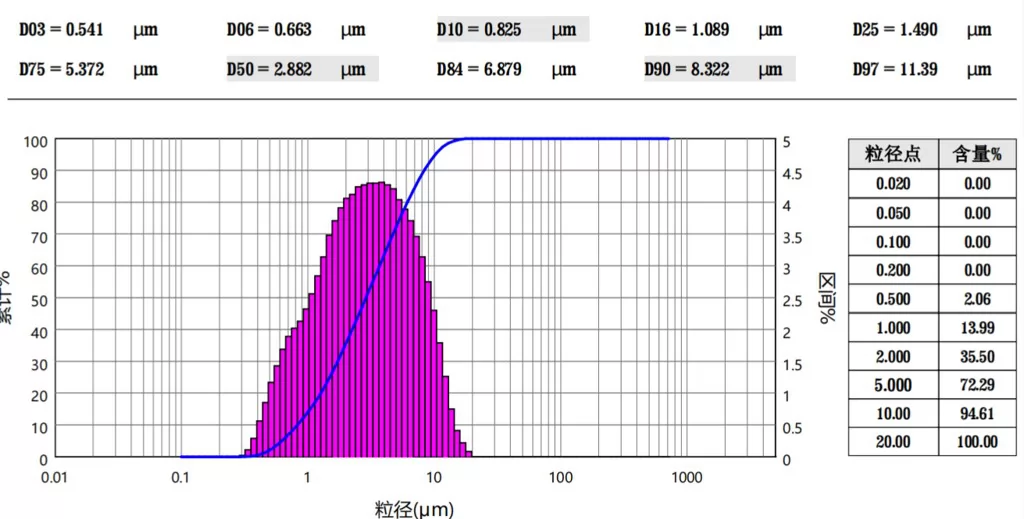

As PVC compounding manager at AsiaCables, we needed REACH-compliant flame retardants without sacrificing UL94 V-0 performance. KMT's HM2V hydromagnesite (D50=3.1μm) delivered 22% faster self-extinguishing times versus ATO in our 160°C processing lines. Passed IEC 60332-1 with 15phr loading.

Rajiv Kapoor - IN

5/5 stars

Apr 10.2024

Our automotive hose plant struggled with ATO's yellowing effect. Implemented KMT's HM2SA (≥92 whiteness) across 3 shifts. Eliminated 7% material waste from color correction - maintained 40.5% MgO content while cutting smoke opacity to 62Dm (from 78Dm).

Dr. Müller - DE

5/5 stars

Nov 03.2023

Initially skeptical about mineral FR efficiency in thin-wall PVC. HM2V's patent-coated particles (10-14m²/g BET) enabled 1.2mm insulation thickness at 35% loading - outperformed brominated systems in DIN 54837 vertical burn. Zero halogen compliance achieved Q3 2023.

Yusuf Al-Farsi - OM

5/5 stars

May 31.2023

Transitioned 8,000MT/year EPDM production to HM2S silane grades. 3-stage decomposition matched our 220°C→330°C vulcanization profile. Reduced FR cost/kg by 18% versus ATH blends while maintaining 55 LOI. KMT's Turkey warehouse ensured JIT delivery.

Emma Wallace - GB

5/5 stars

May 03.2023

FR PVC roof membranes required <0.25% acid insolubles. HM2's 0.18% AI kept extrusion dies clean - achieved 98% uptime versus 83% with Chinese hydromagnesite. 50kg/hr throughput maintained at 190°C across 11-week production run.

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products

Copyright © 2024 KMT Industrial (HK)Ltd. All Rights Reserved.

info@kmtindustrial.com

+86-931-7666997

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

What can we help?