English

- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

Article

HM2S vs Ecopiren 3.5C: Performance Comparison Based on HFFR Formulations

This article presents a comparative evaluation of KMT INDUSTRY’s HM2S and Ecopiren 3.5C based on technical data and compound performance. All testing was conducted using High-Filled Flame Retardant (HFFR) formulations.

1. Powder Technical Data Comparison

| Parameter | HM2S | Ecopiren 3.5C |

|---|---|---|

| Bulk Density (g/cm³) | 0.50 | 0.63 |

| Whiteness R457 (%) | 95.5 | 94.5 |

| Oil Absorption (%) | 35 | 33.5 |

| Surface Property | Hydrophobic | Hydrophobic |

| Specific Surface Area (m²/g) | 10–14 | 9–11 |

| Laser Particle Size D50 (μm) | 2.5–3.5 | 4.30 |

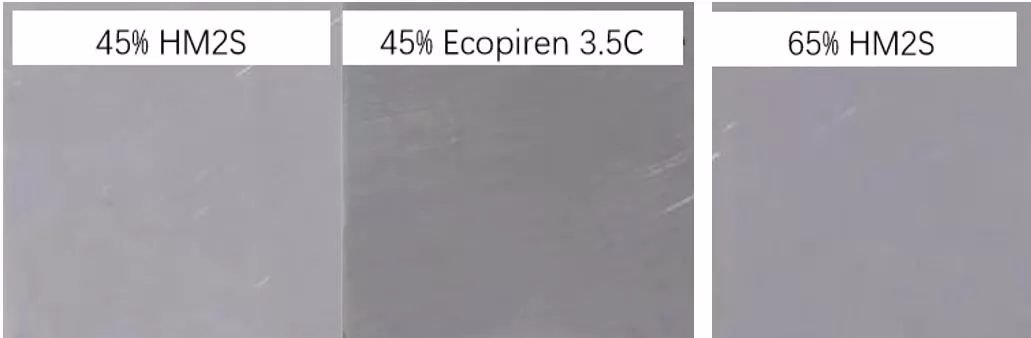

Whiteness compare

-

HM2S

-

Ecopiren 3.5C

PSD:HM2S

Summary:

- HM2S exhibits higher whiteness.

- HM2S shows a finer median particle size (D50).

2. HFFR Compound Performance Evaluation

All compounds used a mixed filler system consisting of aluminum hydroxide (ATH) and magnesium hydroxide (MDH), with a total filler loading of 65% (50% ATH + 15% MDH).

Formula 1 – ATH Grade: 104 LEO

| Parameter | Test Standard | HM2S | Ecopiren 3.5C |

|---|---|---|---|

| Torque (N·m) | — | 2.64 | 2.86 |

| Volume Resistivity (Ω·cm, 5000 V) | GB/T 1410-2006 | 9.59 × 10¹⁴ | 1.39 × 10¹⁵ |

| Melt Flow Index (190 °C / 10 kg) | GB/T 3682 / ASTM D1238 | 0.38 | 0.25 |

| Tensile Strength (MPa) | CB/T 32129-2015 | 16.9 | 15.4 |

| Elongation at Break (%) | CB/T 32129-2015 | 139 | 128 |

| Limiting Oxygen Index (LOI) | GB/T 2406.2 / ASTM D2863 | 40.5 | 40.0 |

| Burning Drops | YES / NO | NO | YES |

Key Findings: HM2S demonstrates lower torque and higher melt flow index, indicating easier processing. It also shows improved mechanical performance and achieves no burning drops in vertical burning tests.

Formula 2 – ATH Grade: KMT A1

| Parameter | HM2S | Ecopiren 3.5C |

|---|---|---|

| Torque (N·m) | 2.99 | 3.06 |

| Tensile Strength (MPa) | 17.3 | 15.7 |

| Elongation at Break (%) | 143 | 142 |

| Burning Drops | NO | YES |

Formula 3 – ATH Grade: 40CD

| Parameter | HM2S | Ecopiren 3.5C |

|---|---|---|

| Torque (N·m) | 2.96 | 3.35 |

| Tensile Strength (MPa) | 17.3 | 16.3 |

| Elongation at Break (%) | 130 | 137 |

| Burning Drops | NO | YES |

3. Overall Conclusion

- Fire Performance: HM2S achieved no burning drops across all tested HFFR formulations.

- Processing Behavior: Consistently lower torque values indicate easier processing.

- Mechanical Properties: Higher tensile strength was observed in all formulations.

- Powder Appearance: HM2S provides higher whiteness in raw material form.

Contact Information

For detailed test reports, samples, or formulation support, please contact KMT INDUSTRY.

0

Comments

Leave a Comment

Your email address will not be published. Required fields are marked *

Your Name*

Your Email*

Hot Article

Need More Help?

Give us a e-mail and chat with our team today!

Get Started

You Might Also Like...

-

2026-Jan-22AM3V: The Next-Generation Flame Retardant Replacing ATO in PVC CompoundsDiscover AM3V, KMT Industrial’s innovative flame retardant replacing ATO in PVC compounds. Achieve high LOI (≥30), low smoke density, and 1/15th the cost.

-

2026-Jan-19How Magnesium Hydroxide Affects Polymer Rheology and ProcessingDiscover how magnesium hydroxide (MDH) affects polymer rheology and processing. Learn expert solutions for optimizing extrusion, injection molding, and compounding of HFFR flame retardant compounds. Technical guide for polymer engineers and manufacturers.

-

2026-Jan-13How to Choose the Best Magnesium Hydroxide Flame Retardant SupplierSelecting the right MDH supplier is critical for HFFR performance. This guide covers technical grades, surface coatings, and global compliance. Learn more with KMT Industrial.

Contact Us Now

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products

Copyright © 2024 KMT Industrial (HK)Ltd. All Rights Reserved.

info@kmtindustrial.com

+86-931-7666997

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

What can we help?