- Home

- About Us

-

Products

.png)

-

Application

.png)

-

Blog

.png)

- Contact us

What Is the Optimal MDH Loading to Reach UL94 V-0?

For engineers and product designers working with thermoplastic materials, the quest to achieve UL94 V-0 certification while maintaining acceptable mechanical properties represents one of the most significant challenges in materials development.

Magnesium dihydroxide (MDH), also known as magnesium hydroxide, has emerged as the leading halogen-free flame retardant for high-temperature applications, offering an effective path to V-0 compliance without the environmental and health concerns associated with brominated alternatives.

- Polymer type and combustion characteristics

- Processing conditions and temperatures

- Particle size and surface treatment

- Specific performance requirements of the end application

1. Understanding Magnesium Dihydroxide as a Flame Retardant

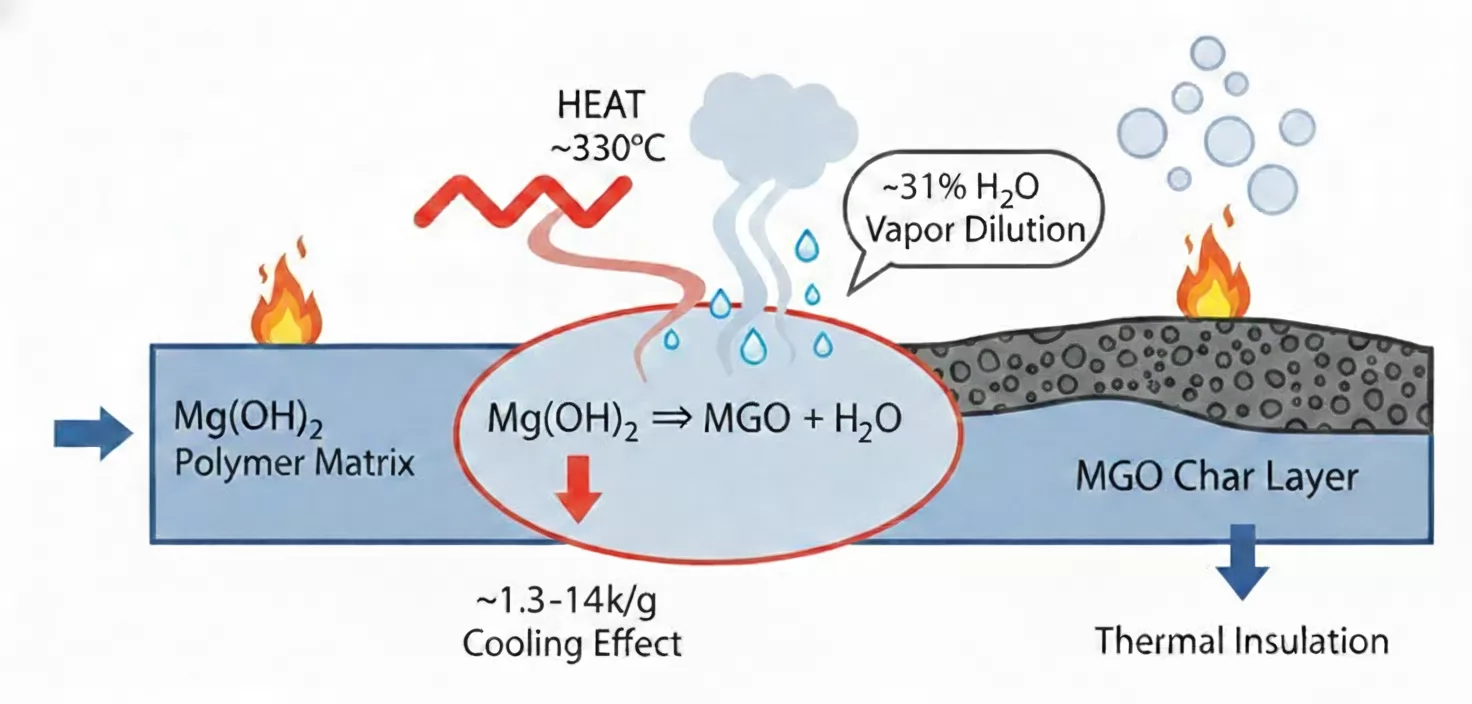

Magnesium dihydroxide operates through a dual-mechanism approach that makes it highly effective for flame retardancy in polymer applications:

Endothermic Decomposition

Mg(OH)₂ → MgO + H₂O at ~330°C

Absorbs 1.3–1.4 kJ/g, effectively cooling the material surface.

Water Vapor Release

Releases approximately 31% of mass as water vapor.

Dilutes flammable gases in combustion zone

Char Layer Formation

Forms protective MgO residue

Insulates underlying polymer from thermal degradation

MDH vs ATH: Key Advantages

The thermal stability of MDH represents its primary advantage over aluminum trihydroxide (ATH):

| Property | MDH | ATH |

|---|---|---|

| Decomposition Temperature | ~330°C | 200-220°C |

| Decomposition Energy | 1.316 kJ/g | 1.051 kJ/g |

| Heat Capacity | 17% higher | Baseline |

| Char Layer | MgO - more robust | Al₂O₃ |

2. UL94 V-0 Testing Requirements and Performance Criteria

The UL94 vertical burn test, administered by Underwriters Laboratories, represents the industry standard for evaluating the flammability of plastic materials used in device enclosures and parts.

UL94 Classification Levels

| Rating | Extinguishing Time | Flaming Drips | Glowing Combustion |

|---|---|---|---|

| V-0 | ≤10 seconds | Not permitted | ≤30 seconds |

| V-1 | ≤30 seconds | Not permitted | ≤60 seconds |

| V-2 | ≤30 seconds | Permitted | ≤60 seconds |

- Self-extinguish within 10 seconds after each of two 10-second flame applications

- No flaming drips permitted that could ignite the underlying cotton indicator

- No glowing combustion persisting for more than 30 seconds after second flame removal

- Minimum 5 specimens must meet all criteria

3. Optimal MDH Loading Percentages by Polymer Type

The MDH loading required to achieve UL94 V-0 certification varies significantly depending on the base polymer matrix, with typical loadings ranging from 45% to 65% by weight.

Polymer-Specific Loading Requirements

| Polymer Type | MDH Loading (MDH Alone) | Reduced with Synergists | Key Considerations |

|---|---|---|---|

| Polypropylene (PP) | 60-65 wt% | 20-30 wt% (with IFR) | High loading impacts impact strength; synergists essential |

| Polyethylene (PE) | 55-60 wt% | 30-40 wt% | Lower processing temps allow standard MDH grades |

| Polyamide (PA/Nylon) | 50-60 wt% | 35-45 wt% | Surface treatment critical for compatibility |

| EVA | 50-55 wt% | 30-40 wt% | Excellent MDH compatibility; good processability |

Key Insights by Polymer

Polypropylene

Most challenging due to low LOI (17-18%) and low char-forming tendency.

MDH alone: 60-65%

With IFR systems: 20-25%

Polyethylene

Requires 55-60% MDH alone.

Lower processing temperatures allow standard MDH grades.

Polyamide (Nylon)

Requires 50-60% MDH.

High processing temps (>250°C) necessitate MDH.

Surface-treated grades critical.

EVA

Most compatible with MDH due to polar nature.

Excellent processability and balanced properties.

4. Critical Factors Affecting MDH Effectiveness

While loading percentage represents the primary determinant of flame retardancy, the effectiveness of MDH in achieving UL94 V-0 depends heavily on several secondary factors.

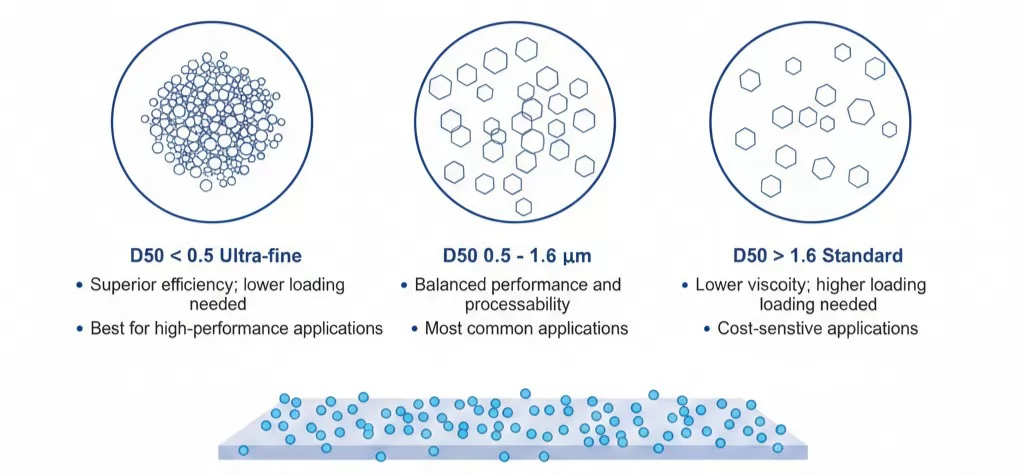

4.1 Particle Size and Distribution

The particle size distribution of MDH fundamentally affects flame retardant efficiency, dispersion quality, and mechanical properties. Finer particle sizes provide better flame retardancy performance due to increased surface area for heat absorption.

Ultra-fine

Superior efficiency; lower loading needed

Best for high-performance applications

Fine

Balanced performance and processability

Most common applications

Standard

Lower viscosity; higher loading needed

Cost-sensitive applications

- P1 (Ultra-Fine Grade): Our premium ultra-fine MDH with a controlled particle size of 0.8–1.2 μm, designed for high-end flame retardant systems.

- PM5S (Super Fine Grade): A high-performance MDH exemplifying modern super fine technology. With a D50 of 1.4–1.7 μm and specialized silane surface coating, it ensures excellent dispersion and prevents agglomeration during storage and processing.

4.2 Surface Treatment and Compatibility

Surface treatment of MDH particles is one of the most critical factors for successful formulation of high-loading flame retardant systems. Untreated MDH exhibits poor compatibility with most polymer matrices.

Silane (Amino)

Best for: Polyamide, Epoxy

Provides strong chemical bonding

Silane (Vinyl)

Best for: Polyolefins (PP, PE)

Provides good compatibility

Silane (Epoxy)

Best for: Epoxy, Thermosets

Provides crosslinking capability

Titanate

Best for: Various polymers

Provides up to 56.8% strength enhancement

4.3 Synergistic Additives

The incorporation of synergistic additives offers a powerful strategy for reducing the total MDH loading required to achieve UL94 V-0 certification.

| Synergist | Loading Level | Mechanism | MDH Loading Reduction |

|---|---|---|---|

| Zinc Borate (ZB) | 3-8 wt% | Enhanced char formation, smoke suppression | 5-10 percentage points |

| Nanoclay (MMT) | 1-5 wt% | Physical barrier, reinforced char | 3-8 percentage points |

| APP (Intumescent) | 10-20 wt% | Char expansion, gas phase action | 30-40 percentage points (with PE/PP) |

5. Processing Considerations and Mechanical Property Trade-offs

The high loading levels required for MDH-based flame retardant systems inevitably impact processing characteristics and mechanical properties.

5.1 Processing Challenges

Increased Viscosity

Impact: Difficult injection molding, extrusion

Solution: Twin-screw extruder with optimized screw design

Shear Heating

Impact: Risk of polymer degradation

Solution: Careful temperature control

Filler Distribution

Impact: Non-uniform flame retardancy

Solution: Ultra-fine, surface-treated MDH grades

5.2 Mechanical Property Trade-offs

Tensile Strength

Improves at moderate loading; degrades at high loading (>60%)

Mitigation: Surface treatment, optimal loading level

Flexural Modulus

Generally improves (reinforcing effect)

Mitigation: Fine particle size for better dispersion

Impact Strength

Decreases progressively

Mitigation: Surface treatment, impact modifiers, titanate coupling

Elongation at Break

Decreases with loading

Mitigation: Balanced formulation, compatibilizers

5.3 Cost Considerations

MDH Cost Advantage

Generally less expensive than synthetic halogenated flame retardants

Loading Impact

High loadings (50-65%) can increase overall formulation volume and cost

Regulatory Trend

Increasing restrictions on halogenated flame retardants favor MDH solutions

Total Cost of Ownership

Environmental compliance and reduced regulatory risk offset higher loading costs

6. Comparison with Alternative Flame Retardant Systems

MDH offers several significant advantages over alternative flame retardant technologies. The higher decomposition temperature of MDH (330°C versus 200-220°C for ATH) enables processing of engineering polymers that require elevated temperatures during compounding and molding.

MDH Advantages

- Higher decomposition temperature (330°C) enables processing of engineering polymers

- Superior flame quenching due to higher decomposition energy and heat capacity

- More robust char formation (MgO) compared to ATH (Al₂O₃)

- Environmental advantages - fully halogen-free and non-toxic

- Smoke suppression properties valuable for enclosed applications

Halogenated Concerns

- Environmental and health concerns

- Increasing regulatory restrictions

- Restrictions on decaBDE and other brominated compounds

- Driving adoption of halogen-free alternatives like MDH

7. Practical Recommendations for Formulating MDH-Based V-0 Systems

Step-by-Step Formulation Guide

Select MDH Grade

Choose based on polymer and processing temperature

Use MDH for polymers >220°C; select D50 < 2 μm for best efficiency

Verify Surface Treatment

Ensure compatibility with polymer matrix

Silane for polyamides; vinyl for polyolefins; titanate for impact strength

Add Synergists

Incorporate zinc borate or nanoclay

3-8% zinc borate for char enhancement; 1-5% nanoclay for barrier effect

Optimize Compounding

Use twin-screw extruder with proper screw design

Control temperature to avoid polymer degradation

Test and Validate

Conduct UL94 testing and mechanical testing

Test actual parts or molded test bars per UL94 requirements

Quick Reference: Key Decision Points

For PP/PE processed below 220°C

Consider ATH for cost savings; use MDH for higher thermal stability requirements

For engineering polymers (>220°C)

MDH is essential - ATH will decompose prematurely

For critical impact strength

Use titanate-treated MDH; consider impact modification additives

For cost optimization

Add 3-8% zinc borate synergist to reduce MDH requirements

For maximum efficiency

Use intumescent systems (APP-based) for PP/PE to achieve V-0 at 20-30% total loading

8. Conclusion

- Loading levels: 50-65% for MDH alone; can be reduced to 20-40% with synergists

- Particle characteristics: Super fine grades (D50 < 2.0 μm) for best efficiency

- Surface treatments: Silane or titanate coupling for compatibility

- Synergistic combinations: Zinc borate, nanoclay, or intumescent systems

MDH's higher decomposition temperature (330°C) compared to ATH makes it the essential choice for engineering polymers processed above 220°C, while its environmental advantages position it favorably as regulatory restrictions on halogenated alternatives continue to expand.

The key to successful formulation lies in balancing the trade-offs between flame retardancy, mechanical properties, processing characteristics, and cost. By understanding the fundamental mechanisms of MDH flame retardancy, the specific requirements of UL94 V-0 testing, and the practical considerations for each polymer system, engineers can develop MDH-based formulations that reliably achieve V-0 certification while meeting all other application requirements.

As the demand for halogen-free flame retardant solutions continues to grow across electronics, construction, and transportation applications, MDH technology will remain at the forefront of safe and effective flame retardancy solutions.

Contact KMT Industrial's technical team to discuss your specific application requirements and explore how our premium magnesium hydroxide products can help you achieve V-0 certification in your flame retardant formulations.

Your Name*

Your Email*

-

2026-Jan-30What Is the Optimal MDH Loading to Reach UL94 V-0?Master MDH loading strategies for UL94 V-0 certification. Get polymer-specific loading percentages, formulation tips, and synergistic additive recommendations from KMT Industrial's technical experts.

-

2026-Jan-22AM3V: The Next-Generation Flame Retardant Replacing ATO in PVC CompoundsDiscover AM3V, KMT Industrial’s innovative flame retardant replacing ATO in PVC compounds. Achieve high LOI (≥30), low smoke density, and 1/15th the cost.

-

2026-Jan-19How Magnesium Hydroxide Affects Polymer Rheology and ProcessingDiscover how magnesium hydroxide (MDH) affects polymer rheology and processing. Learn expert solutions for optimizing extrusion, injection molding, and compounding of HFFR flame retardant compounds. Technical guide for polymer engineers and manufacturers.

-

+86-931-7653361

+86-931-7653361 Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China.

Room 1212, 1213, Jinhe Building, No. 1264 Beibinhe West Road, Anning District, Lanzhou City, Gansu Province, China. -

Quick Links

-

Products